Understanding Stainless Steels: 316-L and 17-4PH

At Azoth, stainless steel takes the lead as our workhorse material, and rightfully so! From high end luxury goods, safety critical automotive parts, and almost everything in between - stainless steel is an incredibly versatile and cost-effective material.

This article will provide you with a practical understanding of what stainless steel is and define its key attributes, benefits, and applications. We’ll then delve into the distinctions between two of the most popular alloys, 17-4PH and 316-L stainless steels.

What is Stainless Steel?

Stainless Steel is an iron alloy that contains at least 10.5% chromium, less than 0.8% carbon, and nickel along with various other alloying elements like copper, or manganese. Renowned for its exceptional corrosion resistance, robust mechanical properties, and distinct finishes, stainless steel proves to be a valuable material, well-suited for a diverse range of 3D printing applications.

Stainless steel finds widespread use in various industries such as medical, construction, transportation, energy, luxury goods, and beyond. The make-up of stainless steel can be modified to cater its material properties to different applications. In fact, there are a variety of alloys and grades of stainless steel, each with its distinctive composition and associated benefits. But what properties are they known for?

At Azoth, stainless steel takes the lead as our workhorse material, and rightfully so! From high end luxury goods, safety critical automotive parts, and almost everything in between - stainless steel is an incredibly versatile and cost-effective material.

This article will provide you with a practical understanding of what stainless steel is and define its key attributes, benefits, and applications. We’ll then delve into the distinctions between two of the most popular alloys, 17-4PH and 316-L stainless steels.

Corrosion Resistance

When people think of stainless steel, one of the first things that come to their mind is corrosion resistance. Stainless steels possess a passive layer of chromium oxide that naturally forms on the surface. This layer results from the interaction between chromium and oxygen present in the air or water.

Even if the chromium oxide layer is scratched off or removed, it has the remarkable ability to regenerate, ensuring continuous protection against rusting. This self-healing property is a key factor contributing to the corrosion-resistant reputation of stainless steel.

This quality is prominently showcased in many everyday items like cooking utensils and cutlery, commonly crafted from stainless steel. Routine cleaning using standard products such as dish soap and detergent is sufficient to maintain the material's cleanliness without causing damage to its surface.

This quality extends to more demanding industrial applications as well. Stainless steel exhibits resilience against industrial fluids such as hydraulic oil, lubricants, and various chemicals without succumbing to corrosion. These advantages are particularly evident in sectors like food processing, pharmaceutical equipment, medical devices, and marine applications, to name just a few.

Mechanical Properties

Stainless steel exhibits great strength. After all, it is steel! Its toughness remains reliable even in extreme heat or cold, making it an ideal choice for structural applications that anticipate significant variations in environmental conditions.

Stainless steel’s ductility allows it to bend or stretch without breaking. In conventional manufacturing processes, this ductile quality permits stainless steel sheets to be formed, stretched, or pressed into desired shapes. Generally recognized for good machinability, it's worth noting that certain alloys and specific heat treatments may present challenges during machining compared to others.

The hardness of stainless steel is not uniform across all alloys. Some alloys inherently possess greater hardness than others, while certain alloys can be subjected to heat treatments to enhance hardness. Increased hardness is particularly advantageous in applications where resistance to wear and abrasion is paramount, such as in industrial equipment.

It is important to note that the mechanical properties vary from alloy to alloy and across different grades.

Environmental Impacts

Stainless steel is a remarkably sustainable and recyclable material. With recycling rates approaching 100%, stainless steel can undergo recycling without compromising its inherent properties. This not only diminishes the demand for new raw materials but also mitigates associated environmental impacts. This sustainable characteristic is especially pronounced in the 3D printing process, where material is utilized only where needed.

The inherent corrosion resistance and mechanical properties of stainless steel contribute to favorable life cycle assessments for products made from this material. When compared to similar products made from alternative materials, stainless steel can exhibit prolonged product longevity. This can minimize maintenance and replacement parts, lowering overall waste. Additionally, the corrosion-resistant nature of stainless steel can alleviate the necessity for protective coatings.

Now that we have an understanding of stainless steel, let’s take a closer look at two of the most popular alloys, 316-L and 17-4PH stainless steel.

316-L Stainless Steel

The name “316” comes from the reference number assigned to this alloy from the Society of Automotive Engineers (SAE). The “L” tacked on at the end indicates this alloy as low carbon (no more than 0.03%).

The preference for 316-L arises when corrosion takes precedence, particularly in situations involving contact with hydrogen. Hydrogen, commonly used as a process medium in various applications, deteriorates other materials over time, a phenomenon known as hydrogen embrittlement.

Contrasted with 17-4PH, 316-L is softer. This quality proves advantageous in applications like jewelry, where the lower hardness facilitates easier polishing, and the inherent corrosion resistance withstands exposure to natural oils and daily wear. However, it's important to note that the lower strength of 316-L may limit its suitability for highly structural applications.

Common applications for 316-L include chemical and petrochemical processing, food processing, pharmaceutical equipment, jewelry, medical devices, marine applications, and more.

|

Material |

316-L |

|

Heat treatment |

As Sintered |

|

Ultimate strength |

520 Mpa |

|

Yield strength (0.2%) |

175 Mpa |

|

Hardness |

55 HRB |

|

Elongation |

50% |

17-4PH Stainless Steel

The name “17-4” comes from the composition of this alloy - 17% chromium, 4 % nickel. The “PH” at the end is short for “precipitation hardening,” a form of alloy strengthening. Unlike 316-L, 17-4PH is amenable to heat treatment, enabling the modification of its mechanical properties. This capability allows for the attainment of higher strength and hardness, rendering 17-4PH particularly appealing for structural applications. Unlike 316-L, 17-4PH is weldable as well as magnetic.

Although a mirror-like polish is still achievable, it becomes more challenging due to the higher hardness of 17-4PH. Unlike 316-L, 17-4PH exhibits a lower resistance to corrosion. While still suitable for use in moderately corrosive environments, it may necessitate additional coating or plating.

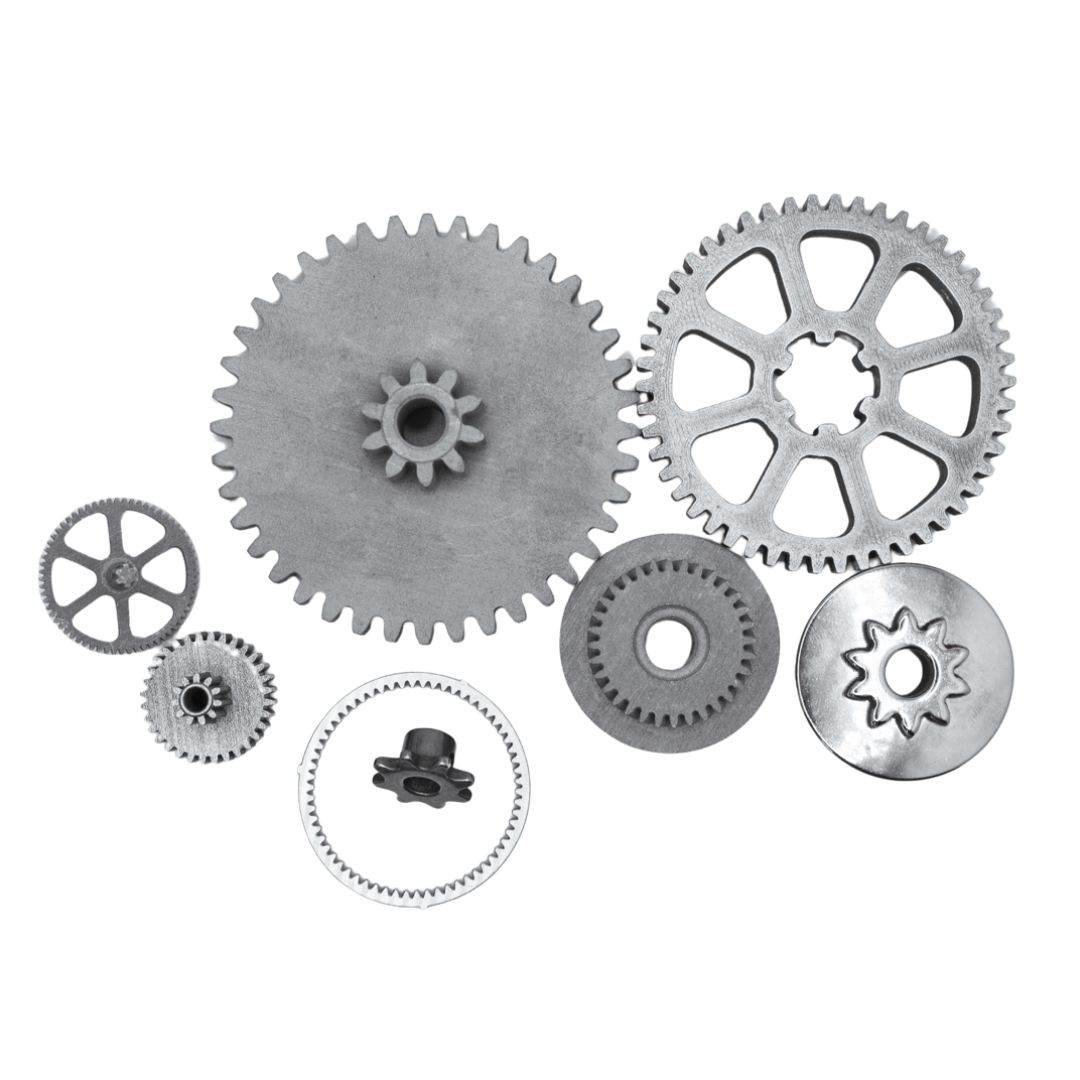

Common applications for 17-4PH include aircraft parts, automotive parts, precision industrial equipment, gears, and more.

|

Material |

17-4PH |

17-4PH |

|

Heat treatment |

As Sintered |

H900 |

|

Ultimate strength |

900 Mpa |

1190 Mpa |

|

Yield strength (0.2%) |

730 Mpa |

1090 Mpa |

|

Hardness |

25 HRC |

38 HRC |

|

Elongation |

6% |

6% |

Steel-ing the Show

Exhibiting exceptional corrosion resistance, strong mechanical properties, aesthetic appeal, and eco-consciousness, stainless steel proves its versatility across a broad spectrum of applications. Whether it's crafting luxury jewelry or manufacturing safety-critical automotive components, Azoth delivers production-ready 3D printed stainless steel parts.

Questions lingering?

Don't hesitate to contact our application engineering team at info@azoth3D.com for any inquiries.

When you're set to roll, submit your parts to Azoth and harness the combined advantages of top-notch stainless steel

and cutting-edge 3D printing technology.