Revolutionizing Aerospace: Cutting-Edge Additive Manufacturing Solutions for Enhanced Performance and Efficiency

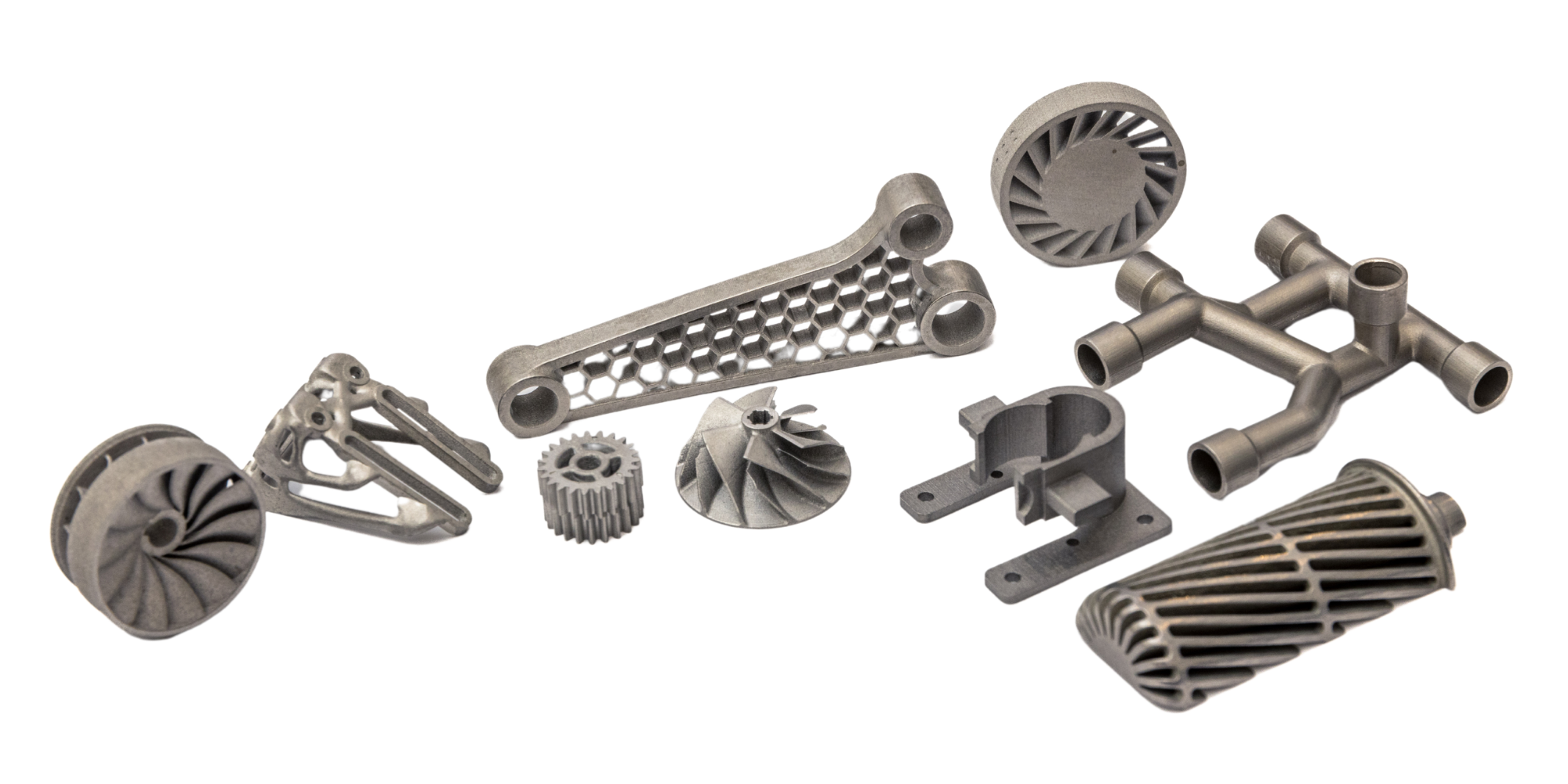

Azoth’s additive (3D) expertise and technology can significantly improve the production of lightweight, complex, small components utilized in aerospace applications. From initial designs to post-processing, Azoth’s team of engineers can work with your engineering team to maximize quality and part performance.

Advanced Aerospace Applications

From prototype to production, Azoth fuels commercial and defense aerospace production through world class metal additive manufacturing.

In aerospace, every ounce counts. Azoth's expertise helps your parts to take flight by employing metal binder jetting to achieve significant weight reduction without compromising structural integrity. Azoth enables each component to be finely tuned to optimize overall performance in the demanding environments of aerospace applications.

Furthermore, Azoth’s technology can seamlessly combine complex assemblies into a single, streamlined component.

Eliminate the long lead times and expediting costs. Azoth accelerates product development by offering rapid prototyping capabilities, enabling customers to swiftly iterate designs and test concepts with unprecedented speed. Through direct digital manufacturing, Azoth builds a more responsive and agile supply chain, eliminating the need for large inventories.

- Production of end-use flightworthy parts

- Maintenance, repair, and overhaul

- Optimized tooling

- Custom jigs and fixturing

- Rapid prototyping

- Durable check gauges and shop-aids

Aerospace Grade Materials

Azoth offers a collection of aerospace grade metals, suitable for a variety of applications.

Centerstage is Mar M247, a nickel-based superalloy renowned for its exceptional strength at elevated temperatures, corrosion and oxidation resistance, and unmatched durability. All of which make it an ideal material for turbine blades, turbine vanes, combustion chambers, and engine components. Coupled with the design freedom Azoth’s technology offers, Mar M247 is a game changer.

Azoth’s aerospace grade 17-4PH stainless steel balances high strength with excellent corrosion resistance. This is essential for aerospace components exposed to environmental conditions, including moisture and salt, but are also structural. 17-4PH stainless steel also has excellent heat treatability, capable of precipitation-hardening to achieve exceptional mechanical properties.

Committed to Quality

Azoth's commitment to quality is evident by our ISO-9001:2015 certification, signifying our dedication to maintaining stringent quality management systems, ensuring consistency, reliability, and continual improvement in our manufacturing processes. Azoth holds ITAR registration and compliance, providing our clients with the assurance of secure and controlled handling of defense-related information and technology. All parts are proudly manufactured in the USA.

Azoth offers a comprehensive range of medical grade materials. We strictly adhere to industry-recognized material standards, including MPIF 35, ASTM B883, and ISO22068. Every part manufactured by Azoth can be traced to its specific lot, allowing for meticulous tracking and accountability throughout the production process.

Our suite of metrology and testing equipment ensures the quality of all parts. Every manufactured component undergoes rigorous dimensional and visual evaluation. After inspection, accepted parts are accompanied by a Certificate of Inspection, verifying that every component conforms to the customers’ requirements.