Azoth’s Additive (3D) Manufacturing Technology can assist in the development of high-performance components that can provide a strategic advantage on the battlefield.

Azoth is ITAR Registered with the United States Government with all its components manufactured in the United States. Azoth’s team of engineers are well versed in the unique needs of the Defense and Firearms Industry and operate to MPIF 35 standards, MIM, ASTM B883 and ISO 22068.

Personal Security:

Serving the Consumer Defense Industry

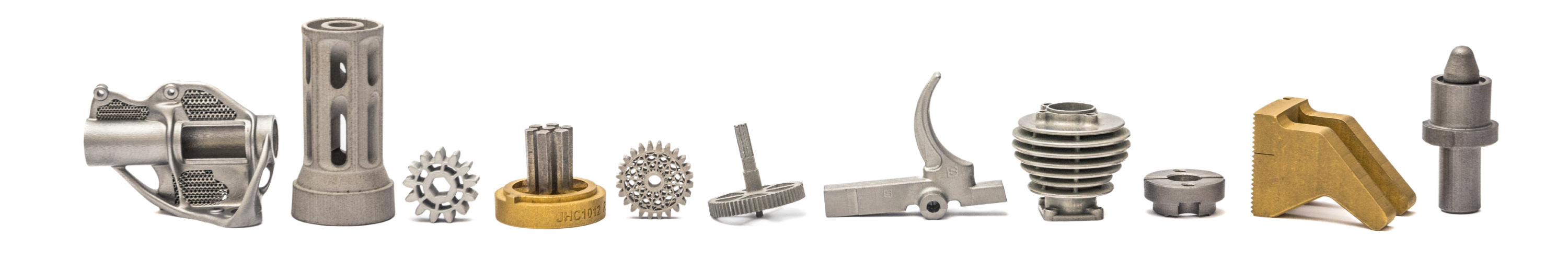

Precision with matchless individuality – See how Azoth combines customization and high accuracy in metal binder jetting additive manufacturing for consumer defense.

Our expertise enables production of bespoke firearm components tailored to precise specifications. We go beyond functionality with unique textures and patterns, crafting distinctive aesthetics and unique tactile experiences.

Elevate performance with component optimization for weight reduction, durability, and enhanced functionality. Choose from a spectrum of coatings, platings, and finishes that improve performance while reflecting your unique style.

- Triggers

- Internal Components

- Slide Caps

- Polymer Frames

- Grips

- Optic Mounts

- Sights

- Mag Releases

- Slide locks

Industrial Defense: Serving National Security

By land, sea, and air, Azoth brings an advantage to the frontlines.

With the highest commitment to security and compliance, Azoth is ITAR registered and compliant, with every component proudly manufactured in the United States.

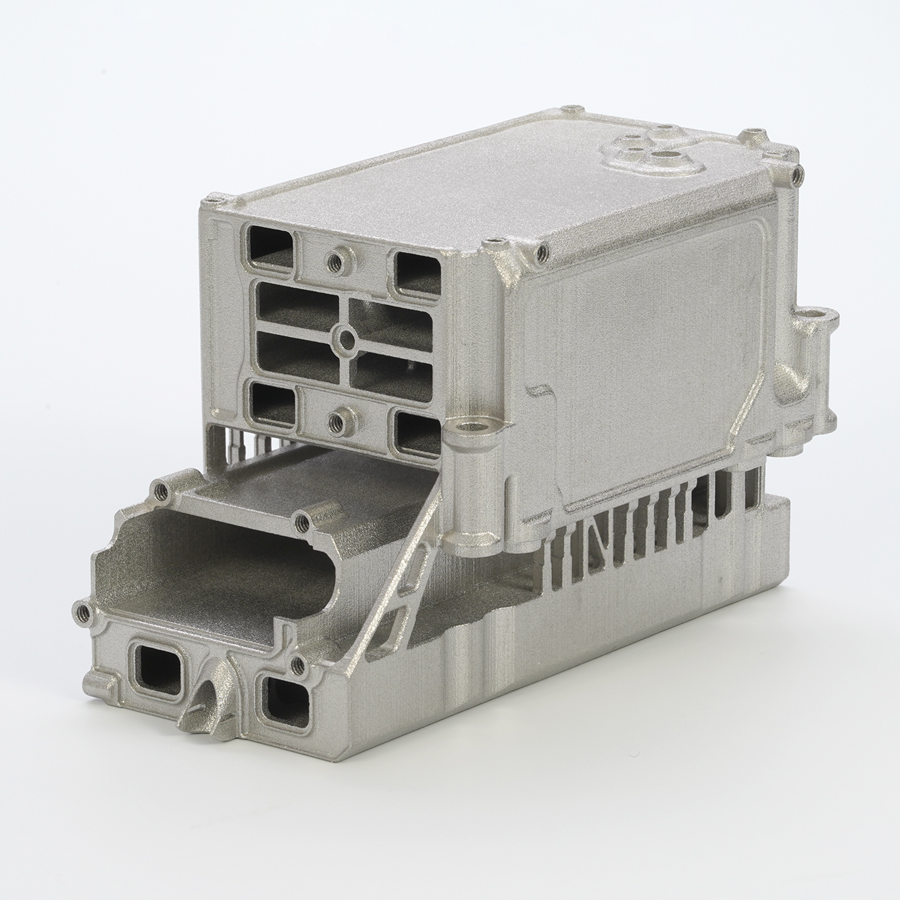

We redefine the pace of progress by bringing defense components to market with unprecedented speeds, fueled by the efficiency of digital manufacturing. Our streamlined approach eliminates the need for extensive inventories, ensuring agility and cost-effectiveness without compromising on quality. Azoth stands capable of meeting the demanding requirements of the defense industry.

Military Vehicles and Equipment

Naval Defense

Electronics

Firearms and Weapon Systems

Communication Systems

Missile Systems

Unmanned Aerial Vehicles

Surveillance and Reconnaissance Systems

Materials and Finishes for the Defense Industry

We offer a variety of materials that follow MPIF 35, ASTM B883, and ISO22068 material standards to ensure the highest quality in defense manufacturing.

- 17-4 PH Stainless Steel

- D2 Tooling Steel

- 4140 Steel

- Ti – 6Al – 4V

- Copper

Our post processing expertise encompasses a spectrum of techniques, including heat treatment, CNC machining, and finishing. Finishes offered include cerakote, powder coat, physical vapor deposition (PVD), plating, and high polish.

Choose Azoth for defense components that go beyond the expected, where our expertise in materials, post-processing, and finishing converges to deliver components that embody the pinnacle of performance and aesthetics.