Azoth’s additive (3D) manufacturing technologies offer new design possibilities, cost-effectiveness, customization, and sustainability.

Azoth’s new technology has revolutionized the way luxury items are produced and consumed. From initial designs, prototype development, to final production, Azoth’s team of engineers can help you at every step along the way.

Watches

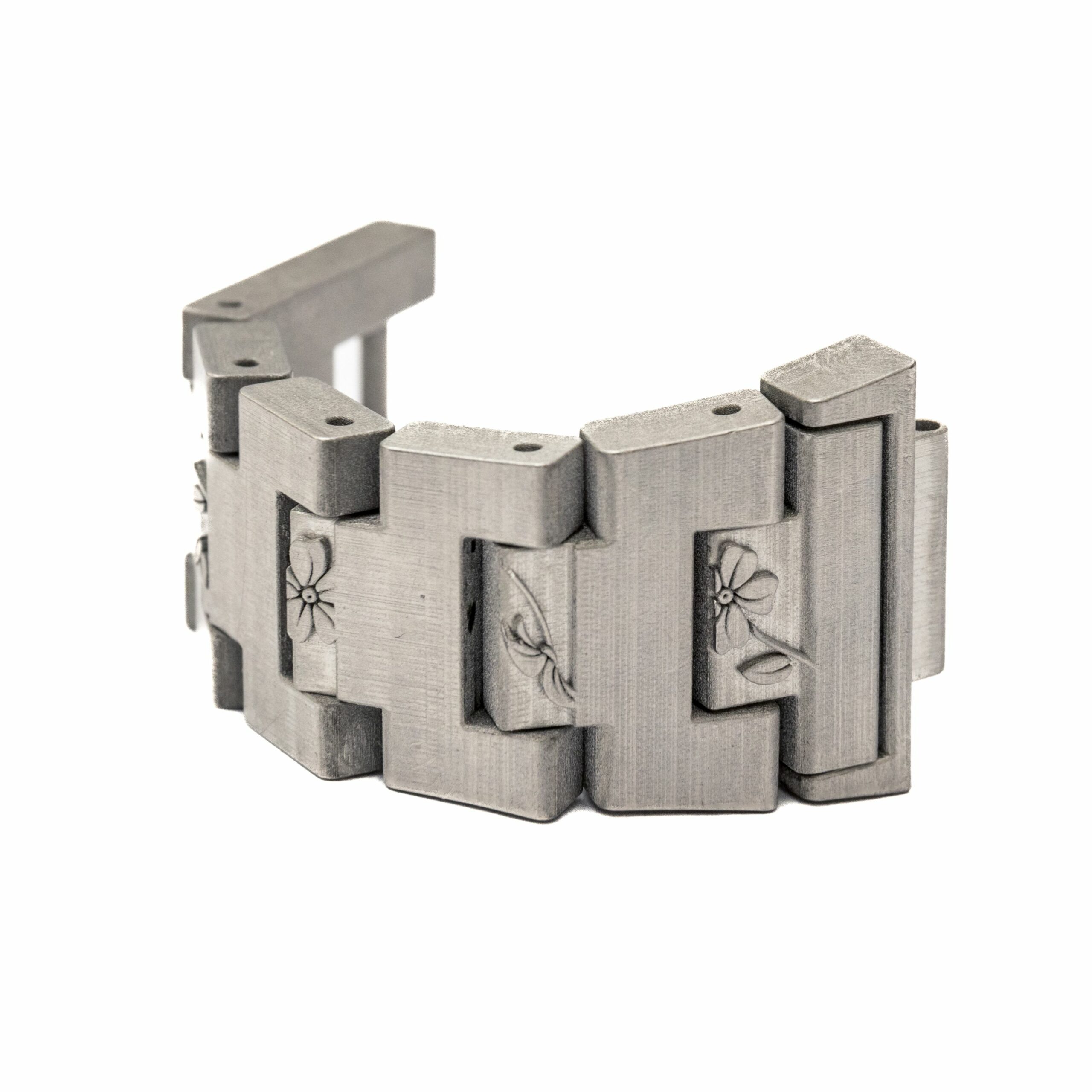

Stay ahead of the times with Azoth’s revolutionary approach to 3D printed luxury watches. Partner with us to infuse additive manufacturing principles to realize novel designs—organic forms, intricate lattice structures, and unique textures to only mention a few.

Leverage customization at scale. From incorporating logos and names to commemorating dates and events, our 3D printed watches are a canvas for your unique story.

Azoth doesn't just consult on design; we're your vertically integrated manufacturing partner. Beyond 3D printing, our capabilities extend to precision machining and post-processing. Our skilled craftsmen meticulously craft each timepiece, achieving mirror-like polishes and offering an array of plating and coating finishes.

Whether it's a limited edition or an exclusive product line, our capabilities extend to low volume production, ensuring each piece is as exceptional as the next. Yet, with scalability at our core, we seamlessly transition to higher volume production when your vision demands it.

Jewelry

Dream it, design it, wear it – In an evolving jewelry industry, embracing the possibilities of 3D printed technology can set your brand apart.

From the first artisan piece to high-fashion, high volume production, we offer a perfect blend of exclusivity and accessibility. Your story becomes tangible through distinctive shapes, personalized engravings, and symbolic elements, making each piece a unique expression of individuality.

- Pendants

- Rings

- Broaches

- Necklaces

- Bracelets

- Earrings

- Beads

- Charms

Elevated Essentials

From functional to fabulous, upgrade commonplace products into a truly unique consumer experience, made possible by the precision and versatility of 3D printing.

While conventional methods simply render these items functional, our expertise and technology allow us to impart them with elaborate details, personalized touches, and a level of craftsmanship that transcends them from their functional origins.