Metal Injection Molding vs. Binder Jetting Metal 3D Printing

In Technical Guides by AZOTH3D

When it comes to making either prototypes or serial production, designers have a range of manufacturing options to choose from. Two options, however, have a few areas in common, complicating the choice.

The two options are Metal Injection Molding (MIM) and Binder Jetting Additive Manufacturing (BJAM). These technologies are particularly well suited to manufacture small, complex geometries. Both can be used individually, but you can also use them together, taking advantage of the best of both, to make a part. It’s not always an either/or choice. As some users are learning, binder jetting can be used in conjunction with MIM, especially when it comes to testing multiple design iterations or addressing low volume needs prior to large volume production with MIM.

First, a general look at each technology.

MIM

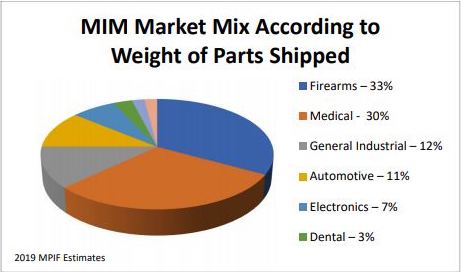

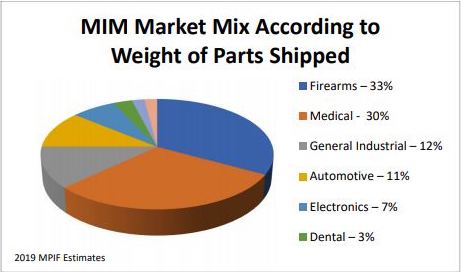

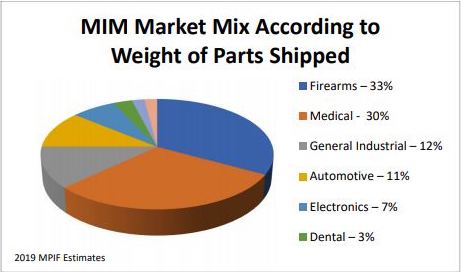

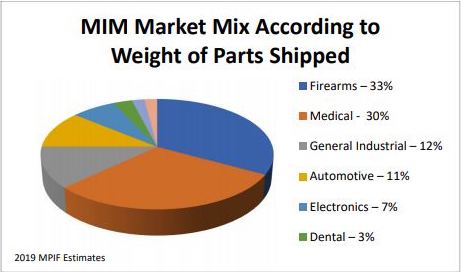

Metal Injection Molding was developed over 40 years ago and experienced major growth through the 1990’s. Today, MIM is a mature technology with many material options and estimated global sales of $2.6 billion. It is widely and reliably used to produce small components in high quantities. Industries that use MIM include firearms, medical, general industrial, dental, electronics, and some automotive.

Most engineers will work with a MIM service provider to avoid the cost of purchasing a MIM machine. The main financial investment for users will be the molds, which have been and still can be costly, ranging from $20K to more than $100K. Thus, a part that is suitable for this technology is one that will not experience design changes for several years or over the production of a high number of parts in order to amortize the mold cost.

Metal Injection Molding was developed over 40 years ago and experienced major growth through the 1990’s. Today, MIM is a mature technology with many material options and estimated global sales of $2.6 billion. It is widely and reliably used to produce small components in high quantities. Industries that use MIM include firearms, medical, general industrial, dental, electronics, and some automotive.

Most engineers will work with a MIM service provider to avoid the cost of purchasing a MIM machine. The main financial investment for users will be the molds, which have been and still can be costly, ranging from $20K to more than $100K. Thus, a part that is suitable for this technology is one that will not experience design changes for several years or over the production of a high number of parts in order to amortize the mold cost.The MIM Process Consists Of Several Steps

–Injection molding of a feedstock, which consist of fine metal powder combined with a binder. The feedstock is inserted into the MIM machine’s hopper. A hydraulic cylinder and screw mechanism puts the material under pressure as it pushes the material into the injection nozzle. This action heats the material, liquifying it so that it can pour into the mold, filling every cavity. The result of the cooled mold is a “green” part.

–Removal of the first stage binder through the use of heat, acid or a solvent. The result is a “brown” part which is porous.

–Thermal debinding during a segment of the sintering cycle which evaporates the remaining binder via the pores left behind in the brown part.

–The final step is completed by increasing to the sintering temperature, in turn closing the porosity in the metal powder which increased the density of the component. The resulting product has mechanical and physical properties similar to parts made conventionally.

The key component of a MIM process is the mold, which must be rugged. It must withstand the high injection pressures of the feedstock which can cause the mold to wear out, in turn, causing the component produced to be out of specifications. This can require multiple molds to be manufactured to achieve the volumes of parts needed.

With MIM, though, it is usually one mold per part. Even though the injection process is fast, often occurring in a second or less, you’re still working on one part at a time. In addition, molds for MIM have geometry constraints similar to molds for other injection molding processes.

Generally, part sizes for MIM vary between .5–50 mm. There are cases of MIM parts in the micro size range with a weight of 0.02 g. Other parts can weigh in excess of 50g, but this is quite rare.

Part size is limited because of the de-binding and sintering processes. Sintering, which occurs at temperatures near a material’s melting point, shrinks a part by as much as 20%. The risk here is loss of part shape, geometry, or tolerance. Thus, the maximum material thickness for de-binding is generally 5 to 10 mm. Thicker parts will either take longer to de-bind or make de-binding impossible.

Shrinkage and distortion are difficult to predict for either MIM or Binder Jetting. Multiple development cycles can be required to achieve the desired dimensional results. With MIM, this means manufacturing a new mold each cycle until a final mold is developed which correctly accounts for the shrinkage and distortion. This makes the MIM development process MONTHS long and very costly, highlighting the main DISADVANTAGE of MIM.

Algorithms are being developed to predict shrinkage and distortion, but are not yet commercially available. Experience combined with trial-and-error is relied upon today.[Reference via]

Binder Jetting

Binder jetting is a newer process and is one of a number of additive manufacturing technologies. Industries that use this technology include medical, firearms, electronics, consumer goods, tooling, aerospace and automotive.

Binder Jetting 3D printers consist of a metal powder recoater combined with a binder application system. In operation, a recoater mechanism applies a thin layer of the metal powder from the hopper holding the raw powder over and onto the build platform. Then, an inkjet style printhead moves over the build platform and deposits the binding material over specific areas that will “grow” as the part. The build platform is then moved down and readied to receive the next layer of powder. This process is repeated until the part or parts are complete.

When the process is complete, the build box holds the completed parts and excess powder. The lose powder is removed to reveal the green parts. These green parts are considered unfinished and some may be physically fragile to handle immediately, so they often rest in the build box while the binder activates. The designation of “green” for these parts means simply that the jetted binder material has bound the metal powder into a part, but that the part has not undergone a debinding or sintering processes.

Like MIM, the completed green part needs additional processing to remove the binder. The green parts first undergo a debinding procedure which results in a “brown part” similar to MIM. Next, sintering occurs when the brown part is heated to near its melting temperature which can approach 1400 C, and the part shrinks roughly 20%. The debinding and sintering steps of the Binder Jetting process are based upon the mature technology established by MIM. The resulting density, mechanical properties, and physical attributes are aligned with MIM and very similar to conventional metalworking technologies.

When To Use MIM; When To Use Binder Jetting

Binder Jetting has become a suitable option when part production volumes go beyond prototyping but remain below the break-even cost of developing a mold for MIM. The cost of a mold will affect the price, but MIM is generally cost-advantageous when part volumes are above 20,000 pieces. Below that, Binder Jetting can be a more cost effective option.

Like other additive technologies, it’s easy to update a design with Binder Jetting, as it is generally just a change in the CAD file. Thus, it’s easy to print out an updated design through the development phases. Changes to a metal mold for MIM can be costly and will take time to make as the process uses traditional machining technologies. Time to market with Binder Jetting can be significantly reduced since multiple design iterations can be made without the lead time and cost associated with MIM molds.

One of the advantages of Binder Jetting is that no supports are needed during a build because the parts are built in a bed of powder. Supports may be needed in the sintering phase to prevent part deformation, depending on the part geometry.

Binder Jetting works well for parts that are small (usually below 50g) with complex geometries. A design tip to keep in mind is that shrinkage and deformation during the sintering phase can be difficult to control if a part is larger than 50 mm. The minimal size limit is around 1 x 1 x 0.5 mm, dictated primarily by current handling constraints.

Binder Jetting handles holes and cavities, fine detail needs with its resolution of 35 um, and wall thicknesses above 0.2mm. Binder Jetting can even be a suitable choice for interlocking and enclosed parts.

The build rates for binder jetting are set based upon the entire build box which is a machine specific rate. How you arrange the parts (packing density) within the build box drives how many parts can be printed. Parts with similar Z axis height will take the same amount of total build time. A build can consist entirely of unique geometries or multiples of the same geometry.

The costs associated with de-binding and sintering depend on the equipment used. In general, the cost of this equipment for MIM and Binder Jetting are very similar. The major cost difference is the Binder Jetting does not require a mold or setup cost like MIM. While the printer itself for BJAM is more expensive than a mold, it can be used for limitless geometries.

The advantage of Binder Jetting when evaluating it with MIM include:

–Few restraints on geometry. Like all additive manufacturing technologies, Binder Jetting handles complex part designs easily.

–Multiple geometries can be printed at once versus MIM which requires a specific mold for each geometry desired

–Time to market: Users can prototype and enter production on the same equipment

–Mass Customization: Incorporate customer specific designs on products since individual molds are not necessary

— Respond to Market Demand: Users can order the minimum parts needed and ramp up accordingly as demand increases. With MIM, minimum part quantities are needed to make it cost effective which may be in excess of the current markets demand.

One of the advantages of MIM, compared to Binder Jetting, is that it can sometimes achieve tighter tolerances on select geometries. Binder Jetting is close to the achievable tolerances today and continues to close this gap. Binder Jetted surface finishes also may not be as smooth as with MIM parts.

Suitable parts for MIM have the following features:

–Part runs of 20,000+ items if the design is suitable for a mold. If these conditions are met, and the part is blow 50g, MIM is the most cost effective technologies in these conditions. If the part run is for fewer parts, consider binder jetting.

Summary

The capabilities between Binder Jetting and MIM are very similar. SO similar in fact, that many consider Binder Jetting “MIM WITHOUT the mold.” For small runs of parts, Binder Jetting is the more cost-effective option. BJAM also enables quicker time to market as well as the ability to test multiple designs without significant increase in cost or time. These advantages can often compliment the MIM Process.

The Binder Jetting market is one of the fast growing segments of the entire Additive Manufacturing landscape. The technology is rapidly evolving, becoming faster and more accurate which unlocks even more potential for the process. Therefore, the breakeven point between Binder Jetting and MIM continues to shift, making Binder Jetting competitive with MIM when it comes to part production. Factor in the ability of Binder Jetting to handle higher design complexity than MIM, and this technology is certainly one that disrupts how the industry considers manufacturing Small, Complex Metal Components.

When it comes to making either prototypes or serial production, designers have a range of manufacturing options to choose from. Two options, however, have a few areas in common, complicating the choice.

The two options are Metal Injection Molding (MIM) and Binder Jetting Additive Manufacturing (BJAM). These technologies are particularly well suited to manufacture small, complex geometries. Both can be used individually, but you can also use them together, taking advantage of the best of both, to make a part. It’s not always an either/or choice. As some users are learning, binder jetting can be used in conjunction with MIM, especially when it comes to testing multiple design iterations or addressing low volume needs prior to large volume production with MIM.

First, a general look at each technology.

MIM

Metal Injection Molding was developed over 40 years ago and experienced major growth through the 1990’s. Today, MIM is a mature technology with many material options and estimated global sales of $2.6 billion. It is widely and reliably used to produce small components in high quantities. Industries that use MIM include firearms, medical, general industrial, dental, electronics, and some automotive.

Most engineers will work with a MIM service provider to avoid the cost of purchasing a MIM machine. The main financial investment for users will be the molds, which have been and still can be costly, ranging from $20K to more than $100K. Thus, a part that is suitable for this technology is one that will not experience design changes for several years or over the production of a high number of parts in order to amortize the mold cost.

Metal Injection Molding was developed over 40 years ago and experienced major growth through the 1990’s. Today, MIM is a mature technology with many material options and estimated global sales of $2.6 billion. It is widely and reliably used to produce small components in high quantities. Industries that use MIM include firearms, medical, general industrial, dental, electronics, and some automotive.

Most engineers will work with a MIM service provider to avoid the cost of purchasing a MIM machine. The main financial investment for users will be the molds, which have been and still can be costly, ranging from $20K to more than $100K. Thus, a part that is suitable for this technology is one that will not experience design changes for several years or over the production of a high number of parts in order to amortize the mold cost.The MIM Process Consists Of Several Steps

–Injection molding of a feedstock, which consist of fine metal powder combined with a binder. The feedstock is inserted into the MIM machine’s hopper. A hydraulic cylinder and screw mechanism puts the material under pressure as it pushes the material into the injection nozzle. This action heats the material, liquifying it so that it can pour into the mold, filling every cavity. The result of the cooled mold is a “green” part.

–Removal of the first stage binder through the use of heat, acid or a solvent. The result is a “brown” part which is porous.

–Thermal debinding during a segment of the sintering cycle which evaporates the remaining binder via the pores left behind in the brown part.

–The final step is completed by increasing to the sintering temperature, in turn closing the porosity in the metal powder which increased the density of the component. The resulting product has mechanical and physical properties similar to parts made conventionally.

The key component of a MIM process is the mold, which must be rugged. It must withstand the high injection pressures of the feedstock which can cause the mold to wear out, in turn, causing the component produced to be out of specifications. This can require multiple molds to be manufactured to achieve the volumes of parts needed.

With MIM, though, it is usually one mold per part. Even though the injection process is fast, often occurring in a second or less, you’re still working on one part at a time. In addition, molds for MIM have geometry constraints similar to molds for other injection molding processes.

Generally, part sizes for MIM vary between .5–50 mm. There are cases of MIM parts in the micro size range with a weight of 0.02 g. Other parts can weigh in excess of 50g, but this is quite rare.

Part size is limited because of the de-binding and sintering processes. Sintering, which occurs at temperatures near a material’s melting point, shrinks a part by as much as 20%. The risk here is loss of part shape, geometry, or tolerance. Thus, the maximum material thickness for de-binding is generally 5 to 10 mm. Thicker parts will either take longer to de-bind or make de-binding impossible.

Shrinkage and distortion are difficult to predict for either MIM or Binder Jetting. Multiple development cycles can be required to achieve the desired dimensional results. With MIM, this means manufacturing a new mold each cycle until a final mold is developed which correctly accounts for the shrinkage and distortion. This makes the MIM development process MONTHS long and very costly, highlighting the main DISADVANTAGE of MIM.

Algorithms are being developed to predict shrinkage and distortion, but are not yet commercially available. Experience combined with trial-and-error is relied upon today.[Reference via]

Binder Jetting

Binder jetting is a newer process and is one of a number of additive manufacturing technologies. Industries that use this technology include medical, firearms, electronics, consumer goods, tooling, aerospace and automotive.

Binder Jetting 3D printers consist of a metal powder recoater combined with a binder application system. In operation, a recoater mechanism applies a thin layer of the metal powder from the hopper holding the raw powder over and onto the build platform. Then, an inkjet style printhead moves over the build platform and deposits the binding material over specific areas that will “grow” as the part. The build platform is then moved down and readied to receive the next layer of powder. This process is repeated until the part or parts are complete.

When the process is complete, the build box holds the completed parts and excess powder. The lose powder is removed to reveal the green parts. These green parts are considered unfinished and some may be physically fragile to handle immediately, so they often rest in the build box while the binder activates. The designation of “green” for these parts means simply that the jetted binder material has bound the metal powder into a part, but that the part has not undergone a debinding or sintering processes.

Like MIM, the completed green part needs additional processing to remove the binder. The green parts first undergo a debinding procedure which results in a “brown part” similar to MIM. Next, sintering occurs when the brown part is heated to near its melting temperature which can approach 1400 C, and the part shrinks roughly 20%. The debinding and sintering steps of the Binder Jetting process are based upon the mature technology established by MIM. The resulting density, mechanical properties, and physical attributes are aligned with MIM and very similar to conventional metalworking technologies.

When To Use MIM; When To Use Binder Jetting

Binder Jetting has become a suitable option when part production volumes go beyond prototyping but remain below the break-even cost of developing a mold for MIM. The cost of a mold will affect the price, but MIM is generally cost-advantageous when part volumes are above 20,000 pieces. Below that, Binder Jetting can be a more cost effective option.

Like other additive technologies, it’s easy to update a design with Binder Jetting, as it is generally just a change in the CAD file. Thus, it’s easy to print out an updated design through the development phases. Changes to a metal mold for MIM can be costly and will take time to make as the process uses traditional machining technologies. Time to market with Binder Jetting can be significantly reduced since multiple design iterations can be made without the lead time and cost associated with MIM molds.

One of the advantages of Binder Jetting is that no supports are needed during a build because the parts are built in a bed of powder. Supports may be needed in the sintering phase to prevent part deformation, depending on the part geometry.

Binder Jetting works well for parts that are small (usually below 50g) with complex geometries. A design tip to keep in mind is that shrinkage and deformation during the sintering phase can be difficult to control if a part is larger than 50 mm. The minimal size limit is around 1 x 1 x 0.5 mm, dictated primarily by current handling constraints.

Binder Jetting handles holes and cavities, fine detail needs with its resolution of 35 um, and wall thicknesses above 0.2mm. Binder Jetting can even be a suitable choice for interlocking and enclosed parts.

The build rates for binder jetting are set based upon the entire build box which is a machine specific rate. How you arrange the parts (packing density) within the build box drives how many parts can be printed. Parts with similar Z axis height will take the same amount of total build time. A build can consist entirely of unique geometries or multiples of the same geometry.

The costs associated with de-binding and sintering depend on the equipment used. In general, the cost of this equipment for MIM and Binder Jetting are very similar. The major cost difference is the Binder Jetting does not require a mold or setup cost like MIM. While the printer itself for BJAM is more expensive than a mold, it can be used for limitless geometries.

The advantage of Binder Jetting when evaluating it with MIM include:

–Few restraints on geometry. Like all additive manufacturing technologies, Binder Jetting handles complex part designs easily.

–Multiple geometries can be printed at once versus MIM which requires a specific mold for each geometry desired

–Time to market: Users can prototype and enter production on the same equipment

–Mass Customization: Incorporate customer specific designs on products since individual molds are not necessary

— Respond to Market Demand: Users can order the minimum parts needed and ramp up accordingly as demand increases. With MIM, minimum part quantities are needed to make it cost effective which may be in excess of the current markets demand.

One of the advantages of MIM, compared to Binder Jetting, is that it can sometimes achieve tighter tolerances on select geometries. Binder Jetting is close to the achievable tolerances today and continues to close this gap. Binder Jetted surface finishes also may not be as smooth as with MIM parts.

Suitable parts for MIM have the following features:

–Part runs of 20,000+ items if the design is suitable for a mold. If these conditions are met, and the part is blow 50g, MIM is the most cost effective technologies in these conditions. If the part run is for fewer parts, consider binder jetting.

Summary

The capabilities between Binder Jetting and MIM are very similar. SO similar in fact, that many consider Binder Jetting “MIM WITHOUT the mold.” For small runs of parts, Binder Jetting is the more cost-effective option. BJAM also enables quicker time to market as well as the ability to test multiple designs without significant increase in cost or time. These advantages can often compliment the MIM Process.

The Binder Jetting market is one of the fast growing segments of the entire Additive Manufacturing landscape. The technology is rapidly evolving, becoming faster and more accurate which unlocks even more potential for the process. Therefore, the breakeven point between Binder Jetting and MIM continues to shift, making Binder Jetting competitive with MIM when it comes to part production. Factor in the ability of Binder Jetting to handle higher design complexity than MIM, and this technology is certainly one that disrupts how the industry considers manufacturing Small, Complex Metal Components.

When it comes to making either prototypes or serial production, designers have a range of manufacturing options to choose from. Two options, however, have a few areas in common, complicating the choice.

The two options are Metal Injection Molding (MIM) and Binder Jetting Additive Manufacturing (BJAM). These technologies are particularly well suited to manufacture small, complex geometries. Both can be used individually, but you can also use them together, taking advantage of the best of both, to make a part. It’s not always an either/or choice. As some users are learning, binder jetting can be used in conjunction with MIM, especially when it comes to testing multiple design iterations or addressing low volume needs prior to large volume production with MIM.

First, a general look at each technology.

MIM

Metal Injection Molding was developed over 40 years ago and experienced major growth through the 1990’s. Today, MIM is a mature technology with many material options and estimated global sales of $2.6 billion. It is widely and reliably used to produce small components in high quantities. Industries that use MIM include firearms, medical, general industrial, dental, electronics, and some automotive.

Most engineers will work with a MIM service provider to avoid the cost of purchasing a MIM machine. The main financial investment for users will be the molds, which have been and still can be costly, ranging from $20K to more than $100K. Thus, a part that is suitable for this technology is one that will not experience design changes for several years or over the production of a high number of parts in order to amortize the mold cost.

Metal Injection Molding was developed over 40 years ago and experienced major growth through the 1990’s. Today, MIM is a mature technology with many material options and estimated global sales of $2.6 billion. It is widely and reliably used to produce small components in high quantities. Industries that use MIM include firearms, medical, general industrial, dental, electronics, and some automotive.

Most engineers will work with a MIM service provider to avoid the cost of purchasing a MIM machine. The main financial investment for users will be the molds, which have been and still can be costly, ranging from $20K to more than $100K. Thus, a part that is suitable for this technology is one that will not experience design changes for several years or over the production of a high number of parts in order to amortize the mold cost.The MIM Process Consists Of Several Steps

–Injection molding of a feedstock, which consist of fine metal powder combined with a binder. The feedstock is inserted into the MIM machine’s hopper. A hydraulic cylinder and screw mechanism puts the material under pressure as it pushes the material into the injection nozzle. This action heats the material, liquifying it so that it can pour into the mold, filling every cavity. The result of the cooled mold is a “green” part.

–Removal of the first stage binder through the use of heat, acid or a solvent. The result is a “brown” part which is porous.

–Thermal debinding during a segment of the sintering cycle which evaporates the remaining binder via the pores left behind in the brown part.

–The final step is completed by increasing to the sintering temperature, in turn closing the porosity in the metal powder which increased the density of the component. The resulting product has mechanical and physical properties similar to parts made conventionally.

The key component of a MIM process is the mold, which must be rugged. It must withstand the high injection pressures of the feedstock which can cause the mold to wear out, in turn, causing the component produced to be out of specifications. This can require multiple molds to be manufactured to achieve the volumes of parts needed.

With MIM, though, it is usually one mold per part. Even though the injection process is fast, often occurring in a second or less, you’re still working on one part at a time. In addition, molds for MIM have geometry constraints similar to molds for other injection molding processes.

Generally, part sizes for MIM vary between .5–50 mm. There are cases of MIM parts in the micro size range with a weight of 0.02 g. Other parts can weigh in excess of 50g, but this is quite rare.

Part size is limited because of the de-binding and sintering processes. Sintering, which occurs at temperatures near a material’s melting point, shrinks a part by as much as 20%. The risk here is loss of part shape, geometry, or tolerance. Thus, the maximum material thickness for de-binding is generally 5 to 10 mm. Thicker parts will either take longer to de-bind or make de-binding impossible.

Shrinkage and distortion are difficult to predict for either MIM or Binder Jetting. Multiple development cycles can be required to achieve the desired dimensional results. With MIM, this means manufacturing a new mold each cycle until a final mold is developed which correctly accounts for the shrinkage and distortion. This makes the MIM development process MONTHS long and very costly, highlighting the main DISADVANTAGE of MIM.

Algorithms are being developed to predict shrinkage and distortion, but are not yet commercially available. Experience combined with trial-and-error is relied upon today.[Reference via]

Binder Jetting

Binder jetting is a newer process and is one of a number of additive manufacturing technologies. Industries that use this technology include medical, firearms, electronics, consumer goods, tooling, aerospace and automotive.

Binder Jetting 3D printers consist of a metal powder recoater combined with a binder application system. In operation, a recoater mechanism applies a thin layer of the metal powder from the hopper holding the raw powder over and onto the build platform. Then, an inkjet style printhead moves over the build platform and deposits the binding material over specific areas that will “grow” as the part. The build platform is then moved down and readied to receive the next layer of powder. This process is repeated until the part or parts are complete.

When the process is complete, the build box holds the completed parts and excess powder. The lose powder is removed to reveal the green parts. These green parts are considered unfinished and some may be physically fragile to handle immediately, so they often rest in the build box while the binder activates. The designation of “green” for these parts means simply that the jetted binder material has bound the metal powder into a part, but that the part has not undergone a debinding or sintering processes.

Like MIM, the completed green part needs additional processing to remove the binder. The green parts first undergo a debinding procedure which results in a “brown part” similar to MIM. Next, sintering occurs when the brown part is heated to near its melting temperature which can approach 1400 C, and the part shrinks roughly 20%. The debinding and sintering steps of the Binder Jetting process are based upon the mature technology established by MIM. The resulting density, mechanical properties, and physical attributes are aligned with MIM and very similar to conventional metalworking technologies.

When To Use MIM; When To Use Binder Jetting

Binder Jetting has become a suitable option when part production volumes go beyond prototyping but remain below the break-even cost of developing a mold for MIM. The cost of a mold will affect the price, but MIM is generally cost-advantageous when part volumes are above 20,000 pieces. Below that, Binder Jetting can be a more cost effective option.

Like other additive technologies, it’s easy to update a design with Binder Jetting, as it is generally just a change in the CAD file. Thus, it’s easy to print out an updated design through the development phases. Changes to a metal mold for MIM can be costly and will take time to make as the process uses traditional machining technologies. Time to market with Binder Jetting can be significantly reduced since multiple design iterations can be made without the lead time and cost associated with MIM molds.

One of the advantages of Binder Jetting is that no supports are needed during a build because the parts are built in a bed of powder. Supports may be needed in the sintering phase to prevent part deformation, depending on the part geometry.

Binder Jetting works well for parts that are small (usually below 50g) with complex geometries. A design tip to keep in mind is that shrinkage and deformation during the sintering phase can be difficult to control if a part is larger than 50 mm. The minimal size limit is around 1 x 1 x 0.5 mm, dictated primarily by current handling constraints.

Binder Jetting handles holes and cavities, fine detail needs with its resolution of 35 um, and wall thicknesses above 0.2mm. Binder Jetting can even be a suitable choice for interlocking and enclosed parts.

The build rates for binder jetting are set based upon the entire build box which is a machine specific rate. How you arrange the parts (packing density) within the build box drives how many parts can be printed. Parts with similar Z axis height will take the same amount of total build time. A build can consist entirely of unique geometries or multiples of the same geometry.

The costs associated with de-binding and sintering depend on the equipment used. In general, the cost of this equipment for MIM and Binder Jetting are very similar. The major cost difference is the Binder Jetting does not require a mold or setup cost like MIM. While the printer itself for BJAM is more expensive than a mold, it can be used for limitless geometries.

The advantage of Binder Jetting when evaluating it with MIM include:

–Few restraints on geometry. Like all additive manufacturing technologies, Binder Jetting handles complex part designs easily.

–Multiple geometries can be printed at once versus MIM which requires a specific mold for each geometry desired

–Time to market: Users can prototype and enter production on the same equipment

–Mass Customization: Incorporate customer specific designs on products since individual molds are not necessary

— Respond to Market Demand: Users can order the minimum parts needed and ramp up accordingly as demand increases. With MIM, minimum part quantities are needed to make it cost effective which may be in excess of the current markets demand.

One of the advantages of MIM, compared to Binder Jetting, is that it can sometimes achieve tighter tolerances on select geometries. Binder Jetting is close to the achievable tolerances today and continues to close this gap. Binder Jetted surface finishes also may not be as smooth as with MIM parts.

Suitable parts for MIM have the following features:

–Part runs of 20,000+ items if the design is suitable for a mold. If these conditions are met, and the part is blow 50g, MIM is the most cost effective technologies in these conditions. If the part run is for fewer parts, consider binder jetting.

Summary

The capabilities between Binder Jetting and MIM are very similar. SO similar in fact, that many consider Binder Jetting “MIM WITHOUT the mold.” For small runs of parts, Binder Jetting is the more cost-effective option. BJAM also enables quicker time to market as well as the ability to test multiple designs without significant increase in cost or time. These advantages can often compliment the MIM Process.

The Binder Jetting market is one of the fast growing segments of the entire Additive Manufacturing landscape. The technology is rapidly evolving, becoming faster and more accurate which unlocks even more potential for the process. Therefore, the breakeven point between Binder Jetting and MIM continues to shift, making Binder Jetting competitive with MIM when it comes to part production. Factor in the ability of Binder Jetting to handle higher design complexity than MIM, and this technology is certainly one that disrupts how the industry considers manufacturing Small, Complex Metal Components.

When it comes to making either prototypes or serial production, designers have a range of manufacturing options to choose from. Two options, however, have a few areas in common, complicating the choice.

The two options are Metal Injection Molding (MIM) and Binder Jetting Additive Manufacturing (BJAM). These technologies are particularly well suited to manufacture small, complex geometries. Both can be used individually, but you can also use them together, taking advantage of the best of both, to make a part. It’s not always an either/or choice. As some users are learning, binder jetting can be used in conjunction with MIM, especially when it comes to testing multiple design iterations or addressing low volume needs prior to large volume production with MIM.

First, a general look at each technology.

MIM

Metal Injection Molding was developed over 40 years ago and experienced major growth through the 1990’s. Today, MIM is a mature technology with many material options and estimated global sales of $2.6 billion. It is widely and reliably used to produce small components in high quantities. Industries that use MIM include firearms, medical, general industrial, dental, electronics, and some automotive.

Most engineers will work with a MIM service provider to avoid the cost of purchasing a MIM machine. The main financial investment for users will be the molds, which have been and still can be costly, ranging from $20K to more than $100K. Thus, a part that is suitable for this technology is one that will not experience design changes for several years or over the production of a high number of parts in order to amortize the mold cost.

Metal Injection Molding was developed over 40 years ago and experienced major growth through the 1990’s. Today, MIM is a mature technology with many material options and estimated global sales of $2.6 billion. It is widely and reliably used to produce small components in high quantities. Industries that use MIM include firearms, medical, general industrial, dental, electronics, and some automotive.

Most engineers will work with a MIM service provider to avoid the cost of purchasing a MIM machine. The main financial investment for users will be the molds, which have been and still can be costly, ranging from $20K to more than $100K. Thus, a part that is suitable for this technology is one that will not experience design changes for several years or over the production of a high number of parts in order to amortize the mold cost.The MIM Process Consists Of Several Steps

–Injection molding of a feedstock, which consist of fine metal powder combined with a binder. The feedstock is inserted into the MIM machine’s hopper. A hydraulic cylinder and screw mechanism puts the material under pressure as it pushes the material into the injection nozzle. This action heats the material, liquifying it so that it can pour into the mold, filling every cavity. The result of the cooled mold is a “green” part.

–Removal of the first stage binder through the use of heat, acid or a solvent. The result is a “brown” part which is porous.

–Thermal debinding during a segment of the sintering cycle which evaporates the remaining binder via the pores left behind in the brown part.

–The final step is completed by increasing to the sintering temperature, in turn closing the porosity in the metal powder which increased the density of the component. The resulting product has mechanical and physical properties similar to parts made conventionally.

The key component of a MIM process is the mold, which must be rugged. It must withstand the high injection pressures of the feedstock which can cause the mold to wear out, in turn, causing the component produced to be out of specifications. This can require multiple molds to be manufactured to achieve the volumes of parts needed.

With MIM, though, it is usually one mold per part. Even though the injection process is fast, often occurring in a second or less, you’re still working on one part at a time. In addition, molds for MIM have geometry constraints similar to molds for other injection molding processes.

Generally, part sizes for MIM vary between .5–50 mm. There are cases of MIM parts in the micro size range with a weight of 0.02 g. Other parts can weigh in excess of 50g, but this is quite rare.

Part size is limited because of the de-binding and sintering processes. Sintering, which occurs at temperatures near a material’s melting point, shrinks a part by as much as 20%. The risk here is loss of part shape, geometry, or tolerance. Thus, the maximum material thickness for de-binding is generally 5 to 10 mm. Thicker parts will either take longer to de-bind or make de-binding impossible.

Shrinkage and distortion are difficult to predict for either MIM or Binder Jetting. Multiple development cycles can be required to achieve the desired dimensional results. With MIM, this means manufacturing a new mold each cycle until a final mold is developed which correctly accounts for the shrinkage and distortion. This makes the MIM development process MONTHS long and very costly, highlighting the main DISADVANTAGE of MIM.

Algorithms are being developed to predict shrinkage and distortion, but are not yet commercially available. Experience combined with trial-and-error is relied upon today.[Reference via]

Binder Jetting

Binder jetting is a newer process and is one of a number of additive manufacturing technologies. Industries that use this technology include medical, firearms, electronics, consumer goods, tooling, aerospace and automotive.

Binder Jetting 3D printers consist of a metal powder recoater combined with a binder application system. In operation, a recoater mechanism applies a thin layer of the metal powder from the hopper holding the raw powder over and onto the build platform. Then, an inkjet style printhead moves over the build platform and deposits the binding material over specific areas that will “grow” as the part. The build platform is then moved down and readied to receive the next layer of powder. This process is repeated until the part or parts are complete.

When the process is complete, the build box holds the completed parts and excess powder. The lose powder is removed to reveal the green parts. These green parts are considered unfinished and some may be physically fragile to handle immediately, so they often rest in the build box while the binder activates. The designation of “green” for these parts means simply that the jetted binder material has bound the metal powder into a part, but that the part has not undergone a debinding or sintering processes.

Like MIM, the completed green part needs additional processing to remove the binder. The green parts first undergo a debinding procedure which results in a “brown part” similar to MIM. Next, sintering occurs when the brown part is heated to near its melting temperature which can approach 1400 C, and the part shrinks roughly 20%. The debinding and sintering steps of the Binder Jetting process are based upon the mature technology established by MIM. The resulting density, mechanical properties, and physical attributes are aligned with MIM and very similar to conventional metalworking technologies.

When To Use MIM; When To Use Binder Jetting

Binder Jetting has become a suitable option when part production volumes go beyond prototyping but remain below the break-even cost of developing a mold for MIM. The cost of a mold will affect the price, but MIM is generally cost-advantageous when part volumes are above 20,000 pieces. Below that, Binder Jetting can be a more cost effective option.

Like other additive technologies, it’s easy to update a design with Binder Jetting, as it is generally just a change in the CAD file. Thus, it’s easy to print out an updated design through the development phases. Changes to a metal mold for MIM can be costly and will take time to make as the process uses traditional machining technologies. Time to market with Binder Jetting can be significantly reduced since multiple design iterations can be made without the lead time and cost associated with MIM molds.

One of the advantages of Binder Jetting is that no supports are needed during a build because the parts are built in a bed of powder. Supports may be needed in the sintering phase to prevent part deformation, depending on the part geometry.

Binder Jetting works well for parts that are small (usually below 50g) with complex geometries. A design tip to keep in mind is that shrinkage and deformation during the sintering phase can be difficult to control if a part is larger than 50 mm. The minimal size limit is around 1 x 1 x 0.5 mm, dictated primarily by current handling constraints.

Binder Jetting handles holes and cavities, fine detail needs with its resolution of 35 um, and wall thicknesses above 0.2mm. Binder Jetting can even be a suitable choice for interlocking and enclosed parts.

The build rates for binder jetting are set based upon the entire build box which is a machine specific rate. How you arrange the parts (packing density) within the build box drives how many parts can be printed. Parts with similar Z axis height will take the same amount of total build time. A build can consist entirely of unique geometries or multiples of the same geometry.

The costs associated with de-binding and sintering depend on the equipment used. In general, the cost of this equipment for MIM and Binder Jetting are very similar. The major cost difference is the Binder Jetting does not require a mold or setup cost like MIM. While the printer itself for BJAM is more expensive than a mold, it can be used for limitless geometries.

The advantage of Binder Jetting when evaluating it with MIM include:

–Few restraints on geometry. Like all additive manufacturing technologies, Binder Jetting handles complex part designs easily.

–Multiple geometries can be printed at once versus MIM which requires a specific mold for each geometry desired

–Time to market: Users can prototype and enter production on the same equipment

–Mass Customization: Incorporate customer specific designs on products since individual molds are not necessary

— Respond to Market Demand: Users can order the minimum parts needed and ramp up accordingly as demand increases. With MIM, minimum part quantities are needed to make it cost effective which may be in excess of the current markets demand.

One of the advantages of MIM, compared to Binder Jetting, is that it can sometimes achieve tighter tolerances on select geometries. Binder Jetting is close to the achievable tolerances today and continues to close this gap. Binder Jetted surface finishes also may not be as smooth as with MIM parts.

Suitable parts for MIM have the following features:

–Part runs of 20,000+ items if the design is suitable for a mold. If these conditions are met, and the part is blow 50g, MIM is the most cost effective technologies in these conditions. If the part run is for fewer parts, consider binder jetting.

Summary

The capabilities between Binder Jetting and MIM are very similar. SO similar in fact, that many consider Binder Jetting “MIM WITHOUT the mold.” For small runs of parts, Binder Jetting is the more cost-effective option. BJAM also enables quicker time to market as well as the ability to test multiple designs without significant increase in cost or time. These advantages can often compliment the MIM Process.

The Binder Jetting market is one of the fast growing segments of the entire Additive Manufacturing landscape. The technology is rapidly evolving, becoming faster and more accurate which unlocks even more potential for the process. Therefore, the breakeven point between Binder Jetting and MIM continues to shift, making Binder Jetting competitive with MIM when it comes to part production. Factor in the ability of Binder Jetting to handle higher design complexity than MIM, and this technology is certainly one that disrupts how the industry considers manufacturing Small, Complex Metal Components.