What Is A Digital Inventory, and Why You Need One

In Technical Guides by AZOTH3D

One of the overlooked benefits of additive technology is its ability to build a part only as needed. The intelligent use of additive manufacturing combined with 3D data makes it possible to create a Digital Inventory of parts.

A digital inventory is really a data record of parts you use or make. A digital inventory reduces the need to stock components, saving time and money. It can also eliminate machine downtime on shop floors and reduce supply chain complexity.

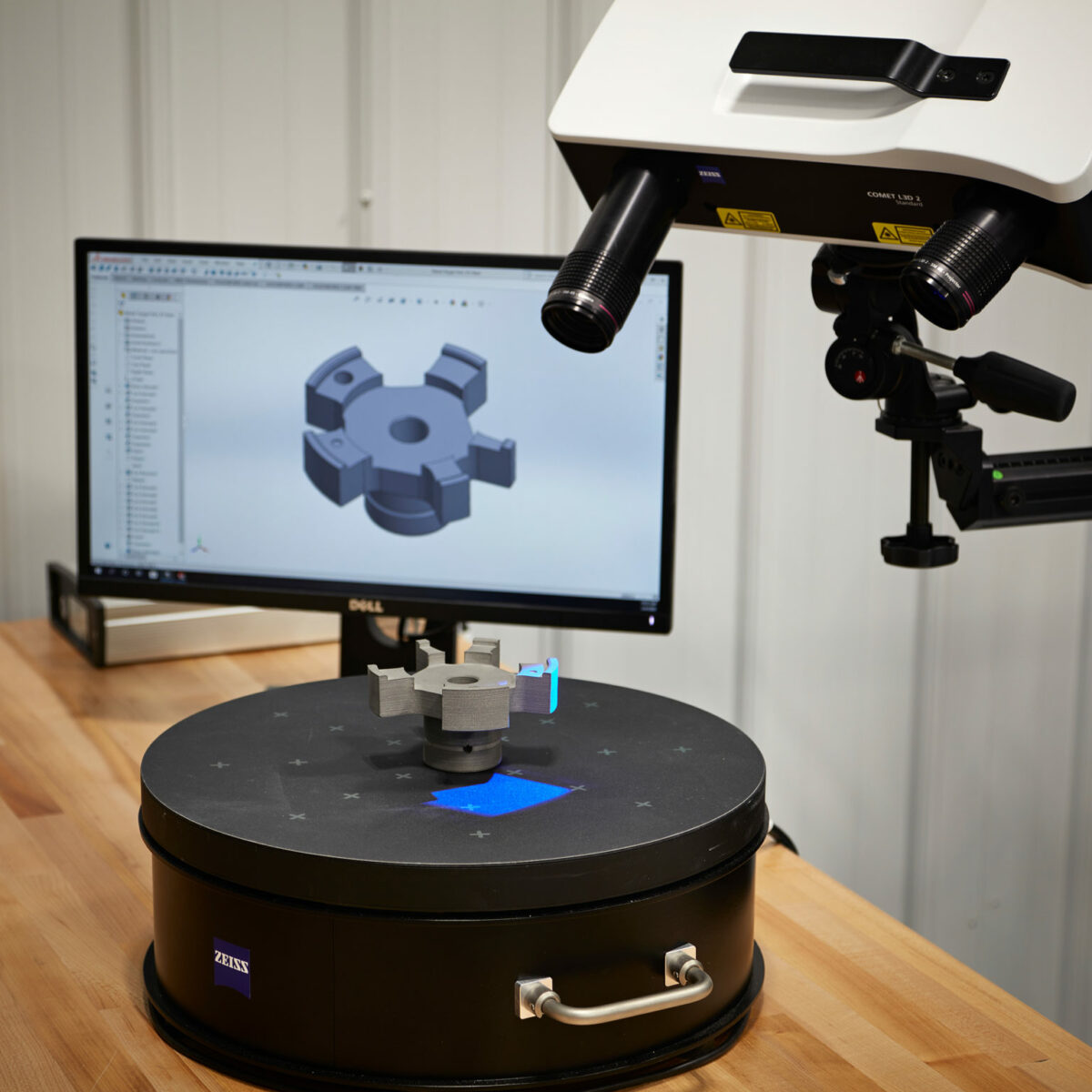

All that’s needed to convert workhorse parts like jigs and fixtures, gripper fingers, blow-off nozzles, gage handles, and so on, is a 3D scanner and CAD software. Many parts may already have a digital CAD file. But for those that do not, someone scans those tools, reverse-engineering them to create a digital file compatible with CAD programs. One bonus of this process is that once you have a CAD file, you can alter the part easily in CAD to suit specific applications. For example, you can have a CAD file on robotic grippers and change the length, gripper shape, load handling capability, and so on to meet specific needs.

The process of creating a digital inventory involves, first, an evaluation of all parts in your inventory. Such a Facility Review will identify all the parts that can be manufactured using additive manufacturing. Not all parts are suitable for building on an additive system, and a good facility review will not force-fit such parts to a specific technology.

But a facility review will streamline your inventory. Specifically, this evaluation looks for:

–Unneeded parts ordered just to meet minimum order quantities

–Parts stored because of their long lead time to produce

–Parts with high failure rates

–Parts no longer needed or usable (but that could be re-engineered).

–Parts capable of being 3D printed on demand.

All of these parts are examples of wasted money, time, and unnecessary complexity in the supply chain.

Once parts are identified, various analyses are done to build the business case to eliminate the excess and convert the part to a digital file. These analyses often include an evaluation of whether a part can be 3D printed using different materials.

Additive technology continues to evolve, and materials for additive are keeping pace, evolving to deliver products with mechanical features that rival materials geared for traditional manufacturing processes. Thus, a tool that was once made from metal may be able to be made from a plastic that offers the needed functions and tolerances.

But you don’t have to have a 3D printer on hand to get your parts made. You can also work with a service bureau that offers additive services. A digital inventory becomes quite advantageous here as many service bureaus are no longer set up to repeatably create parts from a drawing. They work with digital files.

Azoth, for example, offers services that help you create a digital inventory as well as the on-demand printing needed to make parts. The company’s team will examine where complexities exist in your supply chain, where there’s an overload of inventory, or where parts often fail, and build a business case for the conversion.

A critical part of the evaluation involves validation. Before being added to the digitial inventory, Azoth uses a unique process to test and validate all parts prior to being added to the digital inventory. The Azoth team works with the customer process engineers about which parts are best suited to a digital inventory so that manufacturing data is saved and any changes are made to the same blueprint every time.

Azoth uses a model it calls “Take One, Make One.” This is a direct form of on-demand production. When a replacement part is taken, a new part is made. Azoth operates this through synchronization with parts vending machines and ERP/MRP systems that send an order to Azoth’s center.

As for materials, Azoth offers metal and end-use polymer materials. In addition, because the company is vertically integrated, it can deliver finished parts that have undergone post heat treatment, polishing, thread inserts, machining to meet blueprint specifications, and so on.

A digital inventory gives you choices. You can use your own 3D printer to convert a digital file to a part, but you can also work with service bureaus to build your part. Look for a service bureau that will offer post processing and various quality checks, as some parts will need these services more than others. Service bureaus also provide the means to deal with materials and processes that may be hazardous and too expensive to implement in your own facility.

So, instead of storing physical parts in inventory, store them as a data file in your digital inventory. Streamline your supply chain. Reduce your costs. And save time.

Additional Benefits Of A Digital Inventory

- Eliminate 5 to 10-week lead times

- Inventory reduction

- Reduce obsolescence

- Supply chain agility

- Allow engineers to test designs quickly

- NO inventory stocked “just-in-case”

- Eliminate a large vendor base to manage

- Respond to emergency situations

- Don’t use valuable floor space for inventory

Questions To Ask When Evaluating The Need For A Digital Inventory

- Which parts are eligible for 3D printing?

- Which method of printing is right for my parts?

- Which material is right for my parts?

- What is my printer ROI?

- Are my parts designed for additive manufacturing?

- What team members have the skill set to implement?

- Do I purchase printers or use a partner?

- What is my quality management system for On-Demand printing?

One of the overlooked benefits of additive technology is its ability to build a part only as needed. The intelligent use of additive manufacturing combined with 3D data makes it possible to create a Digital Inventory of parts.

A digital inventory is really a data record of parts you use or make. A digital inventory reduces the need to stock components, saving time and money. It can also eliminate machine downtime on shop floors and reduce supply chain complexity.

All that’s needed to convert workhorse parts like jigs and fixtures, gripper fingers, blow-off nozzles, gage handles, and so on, is a 3D scanner and CAD software. Many parts may already have a digital CAD file. But for those that do not, someone scans those tools, reverse-engineering them to create a digital file compatible with CAD programs. One bonus of this process is that once you have a CAD file, you can alter the part easily in CAD to suit specific applications. For example, you can have a CAD file on robotic grippers and change the length, gripper shape, load handling capability, and so on to meet specific needs.

The process of creating a digital inventory involves, first, an evaluation of all parts in your inventory. Such a Facility Review will identify all the parts that can be manufactured using additive manufacturing. Not all parts are suitable for building on an additive system, and a good facility review will not force-fit such parts to a specific technology.

But a facility review will streamline your inventory. Specifically, this evaluation looks for:

–Unneeded parts ordered just to meet minimum order quantities

–Parts stored because of their long lead time to produce

–Parts with high failure rates

–Parts no longer needed or usable (but that could be re-engineered).

–Parts capable of being 3D printed on demand.

All of these parts are examples of wasted money, time, and unnecessary complexity in the supply chain.

Once parts are identified, various analyses are done to build the business case to eliminate the excess and convert the part to a digital file. These analyses often include an evaluation of whether a part can be 3D printed using different materials.

Additive technology continues to evolve, and materials for additive are keeping pace, evolving to deliver products with mechanical features that rival materials geared for traditional manufacturing processes. Thus, a tool that was once made from metal may be able to be made from a plastic that offers the needed functions and tolerances.

But you don’t have to have a 3D printer on hand to get your parts made. You can also work with a service bureau that offers additive services. A digital inventory becomes quite advantageous here as many service bureaus are no longer set up to repeatably create parts from a drawing. They work with digital files.

Azoth, for example, offers services that help you create a digital inventory as well as the on-demand printing needed to make parts. The company’s team will examine where complexities exist in your supply chain, where there’s an overload of inventory, or where parts often fail, and build a business case for the conversion.

A critical part of the evaluation involves validation. Before being added to the digitial inventory, Azoth uses a unique process to test and validate all parts prior to being added to the digital inventory. The Azoth team works with the customer process engineers about which parts are best suited to a digital inventory so that manufacturing data is saved and any changes are made to the same blueprint every time.

Azoth uses a model it calls “Take One, Make One.” This is a direct form of on-demand production. When a replacement part is taken, a new part is made. Azoth operates this through synchronization with parts vending machines and ERP/MRP systems that send an order to Azoth’s center.

As for materials, Azoth offers metal and end-use polymer materials. In addition, because the company is vertically integrated, it can deliver finished parts that have undergone post heat treatment, polishing, thread inserts, machining to meet blueprint specifications, and so on.

A digital inventory gives you choices. You can use your own 3D printer to convert a digital file to a part, but you can also work with service bureaus to build your part. Look for a service bureau that will offer post processing and various quality checks, as some parts will need these services more than others. Service bureaus also provide the means to deal with materials and processes that may be hazardous and too expensive to implement in your own facility.

So, instead of storing physical parts in inventory, store them as a data file in your digital inventory. Streamline your supply chain. Reduce your costs. And save time.

Additional Benefits Of A Digital Inventory

- Eliminate 5 to 10-week lead times

- Inventory reduction

- Reduce obsolescence

- Supply chain agility

- Allow engineers to test designs quickly

- NO inventory stocked “just-in-case”

- Eliminate a large vendor base to manage

- Respond to emergency situations

- Don’t use valuable floor space for inventory

Questions To Ask When Evaluating The Need For A Digital Inventory

- Which parts are eligible for 3D printing?

- Which method of printing is right for my parts?

- Which material is right for my parts?

- What is my printer ROI?

- Are my parts designed for additive manufacturing?

- What team members have the skill set to implement?

- Do I purchase printers or use a partner?

- What is my quality management system for On-Demand printing?

One of the overlooked benefits of additive technology is its ability to build a part only as needed. The intelligent use of additive manufacturing combined with 3D data makes it possible to create a Digital Inventory of parts.

A digital inventory is really a data record of parts you use or make. A digital inventory reduces the need to stock components, saving time and money. It can also eliminate machine downtime on shop floors and reduce supply chain complexity.

All that’s needed to convert workhorse parts like jigs and fixtures, gripper fingers, blow-off nozzles, gage handles, and so on, is a 3D scanner and CAD software. Many parts may already have a digital CAD file. But for those that do not, someone scans those tools, reverse-engineering them to create a digital file compatible with CAD programs. One bonus of this process is that once you have a CAD file, you can alter the part easily in CAD to suit specific applications. For example, you can have a CAD file on robotic grippers and change the length, gripper shape, load handling capability, and so on to meet specific needs.

The process of creating a digital inventory involves, first, an evaluation of all parts in your inventory. Such a Facility Review will identify all the parts that can be manufactured using additive manufacturing. Not all parts are suitable for building on an additive system, and a good facility review will not force-fit such parts to a specific technology.

But a facility review will streamline your inventory. Specifically, this evaluation looks for:

–Unneeded parts ordered just to meet minimum order quantities

–Parts stored because of their long lead time to produce

–Parts with high failure rates

–Parts no longer needed or usable (but that could be re-engineered).

–Parts capable of being 3D printed on demand.

All of these parts are examples of wasted money, time, and unnecessary complexity in the supply chain.

Once parts are identified, various analyses are done to build the business case to eliminate the excess and convert the part to a digital file. These analyses often include an evaluation of whether a part can be 3D printed using different materials.

Additive technology continues to evolve, and materials for additive are keeping pace, evolving to deliver products with mechanical features that rival materials geared for traditional manufacturing processes. Thus, a tool that was once made from metal may be able to be made from a plastic that offers the needed functions and tolerances.

But you don’t have to have a 3D printer on hand to get your parts made. You can also work with a service bureau that offers additive services. A digital inventory becomes quite advantageous here as many service bureaus are no longer set up to repeatably create parts from a drawing. They work with digital files.

Azoth, for example, offers services that help you create a digital inventory as well as the on-demand printing needed to make parts. The company’s team will examine where complexities exist in your supply chain, where there’s an overload of inventory, or where parts often fail, and build a business case for the conversion.

A critical part of the evaluation involves validation. Before being added to the digitial inventory, Azoth uses a unique process to test and validate all parts prior to being added to the digital inventory. The Azoth team works with the customer process engineers about which parts are best suited to a digital inventory so that manufacturing data is saved and any changes are made to the same blueprint every time.

Azoth uses a model it calls “Take One, Make One.” This is a direct form of on-demand production. When a replacement part is taken, a new part is made. Azoth operates this through synchronization with parts vending machines and ERP/MRP systems that send an order to Azoth’s center.

As for materials, Azoth offers metal and end-use polymer materials. In addition, because the company is vertically integrated, it can deliver finished parts that have undergone post heat treatment, polishing, thread inserts, machining to meet blueprint specifications, and so on.

A digital inventory gives you choices. You can use your own 3D printer to convert a digital file to a part, but you can also work with service bureaus to build your part. Look for a service bureau that will offer post processing and various quality checks, as some parts will need these services more than others. Service bureaus also provide the means to deal with materials and processes that may be hazardous and too expensive to implement in your own facility.

So, instead of storing physical parts in inventory, store them as a data file in your digital inventory. Streamline your supply chain. Reduce your costs. And save time.

Additional Benefits Of A Digital Inventory

- Eliminate 5 to 10-week lead times

- Inventory reduction

- Reduce obsolescence

- Supply chain agility

- Allow engineers to test designs quickly

- NO inventory stocked “just-in-case”

- Eliminate a large vendor base to manage

- Respond to emergency situations

- Don’t use valuable floor space for inventory

Questions To Ask When Evaluating The Need For A Digital Inventory

- Which parts are eligible for 3D printing?

- Which method of printing is right for my parts?

- Which material is right for my parts?

- What is my printer ROI?

- Are my parts designed for additive manufacturing?

- What team members have the skill set to implement?

- Do I purchase printers or use a partner?

- What is my quality management system for On-Demand printing?

One of the overlooked benefits of additive technology is its ability to build a part only as needed. The intelligent use of additive manufacturing combined with 3D data makes it possible to create a Digital Inventory of parts.

A digital inventory is really a data record of parts you use or make. A digital inventory reduces the need to stock components, saving time and money. It can also eliminate machine downtime on shop floors and reduce supply chain complexity.

All that’s needed to convert workhorse parts like jigs and fixtures, gripper fingers, blow-off nozzles, gage handles, and so on, is a 3D scanner and CAD software. Many parts may already have a digital CAD file. But for those that do not, someone scans those tools, reverse-engineering them to create a digital file compatible with CAD programs. One bonus of this process is that once you have a CAD file, you can alter the part easily in CAD to suit specific applications. For example, you can have a CAD file on robotic grippers and change the length, gripper shape, load handling capability, and so on to meet specific needs.

The process of creating a digital inventory involves, first, an evaluation of all parts in your inventory. Such a Facility Review will identify all the parts that can be manufactured using additive manufacturing. Not all parts are suitable for building on an additive system, and a good facility review will not force-fit such parts to a specific technology.

But a facility review will streamline your inventory. Specifically, this evaluation looks for:

–Unneeded parts ordered just to meet minimum order quantities

–Parts stored because of their long lead time to produce

–Parts with high failure rates

–Parts no longer needed or usable (but that could be re-engineered).

–Parts capable of being 3D printed on demand.

All of these parts are examples of wasted money, time, and unnecessary complexity in the supply chain.

Once parts are identified, various analyses are done to build the business case to eliminate the excess and convert the part to a digital file. These analyses often include an evaluation of whether a part can be 3D printed using different materials.

Additive technology continues to evolve, and materials for additive are keeping pace, evolving to deliver products with mechanical features that rival materials geared for traditional manufacturing processes. Thus, a tool that was once made from metal may be able to be made from a plastic that offers the needed functions and tolerances.

But you don’t have to have a 3D printer on hand to get your parts made. You can also work with a service bureau that offers additive services. A digital inventory becomes quite advantageous here as many service bureaus are no longer set up to repeatably create parts from a drawing. They work with digital files.

Azoth, for example, offers services that help you create a digital inventory as well as the on-demand printing needed to make parts. The company’s team will examine where complexities exist in your supply chain, where there’s an overload of inventory, or where parts often fail, and build a business case for the conversion.

A critical part of the evaluation involves validation. Before being added to the digitial inventory, Azoth uses a unique process to test and validate all parts prior to being added to the digital inventory. The Azoth team works with the customer process engineers about which parts are best suited to a digital inventory so that manufacturing data is saved and any changes are made to the same blueprint every time.

Azoth uses a model it calls “Take One, Make One.” This is a direct form of on-demand production. When a replacement part is taken, a new part is made. Azoth operates this through synchronization with parts vending machines and ERP/MRP systems that send an order to Azoth’s center.

As for materials, Azoth offers metal and end-use polymer materials. In addition, because the company is vertically integrated, it can deliver finished parts that have undergone post heat treatment, polishing, thread inserts, machining to meet blueprint specifications, and so on.

A digital inventory gives you choices. You can use your own 3D printer to convert a digital file to a part, but you can also work with service bureaus to build your part. Look for a service bureau that will offer post processing and various quality checks, as some parts will need these services more than others. Service bureaus also provide the means to deal with materials and processes that may be hazardous and too expensive to implement in your own facility.

So, instead of storing physical parts in inventory, store them as a data file in your digital inventory. Streamline your supply chain. Reduce your costs. And save time.

Additional Benefits Of A Digital Inventory

- Eliminate 5 to 10-week lead times

- Inventory reduction

- Reduce obsolescence

- Supply chain agility

- Allow engineers to test designs quickly

- NO inventory stocked “just-in-case”

- Eliminate a large vendor base to manage

- Respond to emergency situations

- Don’t use valuable floor space for inventory

Questions To Ask When Evaluating The Need For A Digital Inventory

- Which parts are eligible for 3D printing?

- Which method of printing is right for my parts?

- Which material is right for my parts?

- What is my printer ROI?

- Are my parts designed for additive manufacturing?

- What team members have the skill set to implement?

- Do I purchase printers or use a partner?

- What is my quality management system for On-Demand printing?